| Cite this article as: | Jianliang Zhang, Hongyuan Fu, Yanxiang Liu, Han Dang, Lian Ye, Alberto N. Conejo, and Runsheng Xu, Review on biomass metallurgy: Pretreatment technology, metallurgical mechanism and process design, Int. J. Miner. Metall. Mater., 29(2022), No. 6, pp.1133-1149. https://dx.doi.org/10.1007/s12613-022-2501-9 |

Excessive use of fossil fuels and the increase of greenhouse gases cause climate change, which has become a worldwide concern confronting humanity and presents a major danger to living systems [1–2]. The international convention on environmental issues explicitly proposes to limit the emission of carbon dioxide and other greenhouse gases. China, as the world’s largest energy consumer and CO2 emitter, has likewise pledged to peak carbon emissions by 2030 and have carbon neutral by 2060 [3–4]. The only approach to optimize China’s industrial energy structure and achieve sustainable growth is via the “double carbon” strategy [5–6].

The iron and steel industries are the foundation of China’s social development and provide an important basic guarantee for China’s economic growth and national security. However, second only to the power industry in carbon emissions, China’s steel industry’s overall carbon emissions were 1.8 billion tons in 2020, accounting for >60% of the global carbon emissions from steel production and ~15% of China’s total carbon emissions. The average carbon emission of each ton of crude steel is ~1.7–1.8 t. Therefore, under the background of the “double carbon” strategy, it is urgent to reduce the energy consumption and carbon emissions of China’s iron and steel industry [7−9].

Accelerating the iron and steel industry’s energy structure adjustment, promoting renewable clean energy to replace traditional fossil fuels, and realizing environmentally friendly steel production processes and sustainable energy utilization are the only ways to achieve low-carbon, green, and high-quality development of the iron and steel industry [10−11]. Biomass energy is a type of carbon neutral and ecologically benign renewable energy, and it is a large resource wealth that has been developed and used in China [12]. The use of biomass in the iron and steel industry can not only reduce the consumption of fossil fuels and the emission of greenhouse gases such as CO2 but can also promote a clean and low-carbon energy structure, thereby accelerating the iron and steel industry’s transition to a green and low-carbon future. Biomass (wood charcoal) is the oldest fuel utilized by mankind; however, massive deforestation led to the first energy crisis in European nations from the 16th to the 18th century, and biomass was eventually supplanted by coal [13]. In the early 1800s, a single blast furnace required a circle of forest with a radius of ~4 km once a year, and the charcoal/metal ratio was ~8:1 [14]. Coal (in the form of coke) has been the primary fuel in the iron and steel industry. In recent years, the importance of biomass has been re-evaluated, considering that the quantity of CO2 synthesized by the plants is greater than that produced, thus resulting in a substantial decrease in the carbon foot print. As a result, its application has rapidly developed. Because of several restrictions such as low calorific value, high moisture content, and low volume density, raw biomass requires to be processed before being used in a wide range of applications in both ironmaking and other metallurgy processes [15]. To provide a reference for the development of basic theory and industrial application of biomass metallurgy, this study summarizes the recent research achievements in biomass metallurgy.

Biomass is a renewable organic fuel that is produced by living organisms such as plants and animals. After coal, oil, and natural gas, it is the fourth largest energy source and the sole renewable energy source. Biomass metallurgy refers to the metallurgical technologies that use renewable biomass rich in carbon and hydrogen as the fundamental energy and reducing agent to extract metals. In comparison to conventional coal metallurgy, biomass metallurgy offers the benefit of being carbon neutral, with a significant reduction in CO2 emissions [16–17]. Biomass metallurgy has many benefits over hydrogen metallurgy: The source of biomass is more stable than hydrogen, the price is lower [18–19], the physicochemical features of biomass after transformation can be equivalent to coal, and the equipment investment is lower. For the typical biomass metallurgical roadmap, biomass is treated by physical, chemical, and thermochemical processing and then is used as a reducing agent, fuel, and auxiliary agent in the metallurgical processes, particularly in sintering, coking, blast furnace injection, iron ore reduction, and other metallurgical applications [20–21].

Biomass can be employed in both hydro- and pyro-metallurgical processes, replacing coal and coke. Pyrometallurgy refers to the technique of extracting metal elements and non-metal elements from their ores using reducing agents at high temperatures. It typically depends on fuel combustion to generate heat. In the modern blast furnace process, for example, in the current blast furnace process, coke and pulverized coal are often utilized as reducing and heating agents. The primary reaction mechanism is carbo-thermal reduction, a primary reaction process in which carbon from coke, pulverized coal, and the intermediate product carbon monoxide are used to reduce iron oxides in iron ores. The scientific concept of biomass metallurgy is similar, i.e., the C and H element in biomass are converted into CO, H2, and C required for reducing iron oxides, producing hot metal as shown in chemical reactions (1)–(3).

|

3C + 2Fe2O3=4Fe + 3CO2 |

(1) |

|

3CO+Fe2O3=2Fe + 3CO2 |

(2) |

|

3H2+Fe2O3=2Fe + 3H2O |

(3) |

Biomass can be used as a fuel, and its chemical heat is generated during the combustion reaction to provide the heat required by ironmaking. However, the low energy density of biomass requires upgrading and improvement. The whole chemical reaction is shown in reaction (4):

|

(C−HxOy)m+m(4+x−2y)4O2=mCO2 + xm2H2O |

(4) |

In conclusion, the utilisation principles of renewable biomass and non-renewable fossil fuels (coal, oil, and natural gas) in pyro-metallurgy are essentially identical. However, in the actual process of industrial production, raw biomass requires to be upgraded based on various scenarios to meet the requirements of a safe, stable, and efficient pyro-metallurgical process [22].

Hydro-metallurgy is the chemical reaction between a solution and an ore at low temperatures that transfers metal elements from the ore into the solution, which then separates and enriches the different metal elements in the solution and ultimately extracts the metal or metal compound [23]. Metal element leaching, liquid and solid phase separation, solution purification, metal extraction in solution, and wastewater treatment are the primary operating processes of hydro-metallurgy. Using manganese ore reduction leaching as an example, the most important procedure is to directly reduce Mn4+ in manganese oxide ore to soluble Mn2+ in an adequate solution under acidic conditions before entering the leaching solution. The scientific premise of leaching is that the cellulose in biomass dissociates in acidic conditions to create hydrogen ions, which mix with water to form hydronium ions, thus endowing direct biomass reduction with a clear advantage in this regard. The polysaccharides and monosaccharides formed by the hydrolysis of cellulose macromolecules by hydronium ions have high reducing ability and can quickly reduce tetravalent manganese to divalent manganese. The primary chemical equation is shown in Eq. (5).

|

(C−HxOy)m + 2mMnO2 + m(2y+4−x)H+=2mMn2++mCO2+m(y+2)H2O |

(5) |

The biomass direct reduction leaching process does not require a high roasting temperature and has low energy consumption, less environmental pollution, and low equipment investment. It has become one of the main processes of wet reduction leaching.

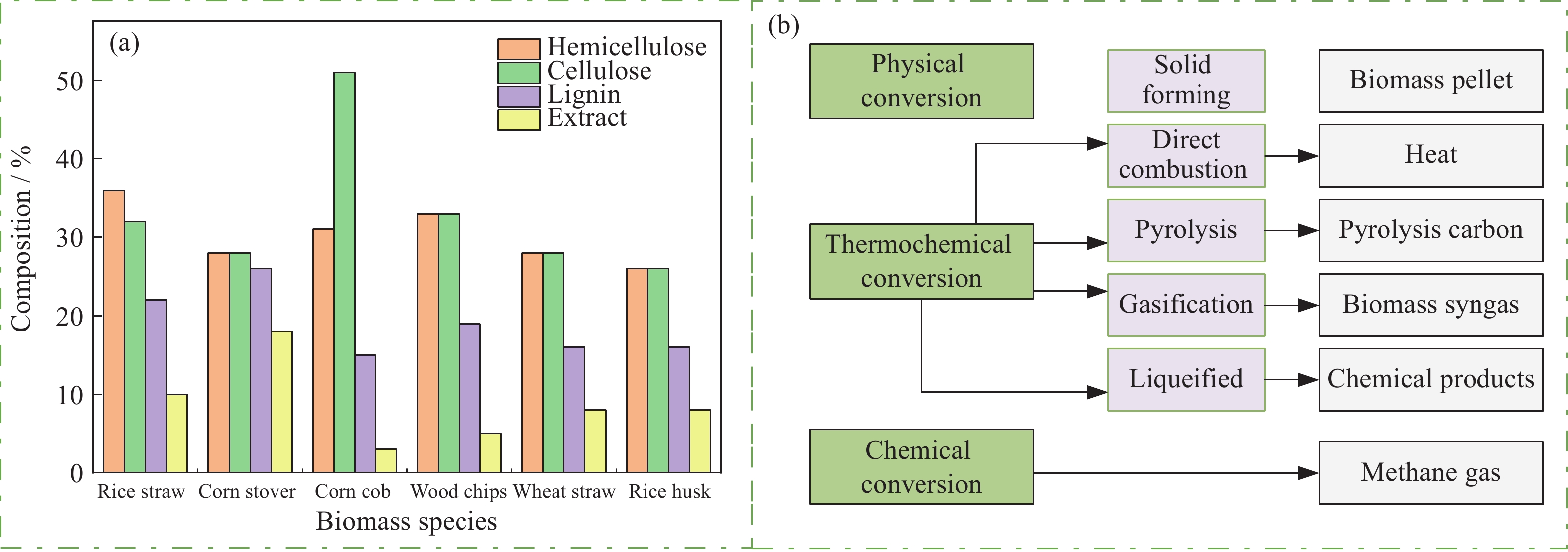

There are several types of biomass, the most common of which are lignin, cellulose, and hemicellulose [24]. Fig. 1(a) shows the lignin, cellulose, and hemicellulose content analysis results of common biomass, which shows the proportions of lignin, cellulose, and hemicellulose contained in different types of biomass are quite different, thus leading to significant differences in the characteristics of different types of biomass [25]. Generalized biomass includes animal manure, residential sewage, industrial organic waste, and municipal solid organic waste, which is an abundant energy supply and a valuable asset. However, most biomass has the characteristics of poor grindability, low volume density, low energy density, and high moisture content [26]. The cost of storing, transporting, and processing biomass is high [27], restricting a widespread application in iron and steelmaking. Therefore, the biomass resource conversion must be required before large-scale application. The pretreatment and transformation technologies of biomass resources include physical transformation, thermochemical transformation, and chemical transformation, and the products produced by various transformation technologies are significantly different, as shown in Fig. 1(b). It is important to choose suitable transformation and treatment methods based on the qualities and application situations of different types of biomass. When biomass is improperly disposed of, such as via landfill buildup, it produces a huge quantity of CH4, which has a global warming potential of 21 times that of CO2 [28]. Moreover, open burning of biomass releases CO2, NOX, and sulfides, all of which have significant detrimental impacts on ecosystem productivity, climate change, and environmental pollution.

Pyrolysis is a process in which biomass is heated to a specific temperature under the condition of air isolation or hypoxia such that biomass particles can be rapidly cracked into pyrolysis char, tar, and non-condensable volatiles of biomass to obtain the necessary solid, liquid, and gaseous products [29]. The characteristics and yield of biomass pyrolysis products are influenced by the properties of biomass and pyrolysis operation parameters, such as the biomass components, pyrolysis temperature, heating rate, pyrolysis duration, and equipment type [27]. According to the different heating rates and pyrolysis times, pyrolysis processes can be divided into very fast pyrolysis, flash pyrolysis, fast pyrolysis, and slow pyrolysis, as shown in Fig. 2(a). Different pyrolysis rates have a substantial impact on the yield of solid, liquid, and gas phases, which can be chosen based on the products required in various application scenarios. Slow pyrolysis is a traditional method for obtaining the solid products with the highest carbon content, which can be used in metallurgical industry, such as iron ore sinter, coking, and blast furnace injection.

Taking the biomass pyrolysis process of agricultural wastes common to palm shell [30] as an sample, the primary pyrolysis interval of biomass is 200–600°C, and the pyrolysis treatment conditions (temperature and time) determine the basic properties of biochar [31–33]. The impact of residence time on the fundamental characteristics of biochar steadily reduces as carbonization temperature rises, and pyrolysis temperature is an essential component in the treatment process [34]. As shown in Fig. 3(b)–(g) [35–36], the microstructure of biochar varies as the treatment temperature and time vary, influencing the macro properties. With the increase in pyrolysis temperature, a large amount of volatile matter escapes from biomass, and many pore structures are generated in the interior and surface of biomass particles. The aromaticity of biochar increased as the pyrolysis temperature increased. Furthermore, the microcrystalline stacking height Lc and the number of microcrystalline stacking layers n progressively rise, the microcrystalline lamellar spacing d002 decreases gradually, the microcrystalline structure tends to be ordered, and the graphitization degree gradually increases.

In comparison to the large amounts of CO2, CH4, and other toxic and harmful flue gases produced by landfill and biomass incineration, a small amount of NOX, sulfides, aldehydes, phenols, and other oxygen-containing harmful substances are produced during biomass pyrolysis, which still has a certain impact on the environment [37]. The lack of understanding of the formation mechanism, distribution law, and control strategy of toxic air limits the safe and efficient development of biomass pyrolysis. Reducing the emission of pollutants is a key step for the large-scale industrial application of pyrolysis char.

Pyrolysis technology can upgrade biomass into high-energy density fuel with higher ordering degree [38]. However, the best pyrolysis parameters should be designed based on the target product’s requirements. Particularly, it is necessary to select the appropriate biomass raw materials, pyrolysis temperature, holding time, and other parameters for the directional preparation of biochar as per the specific application scenarios in the metallurgical industry. For example, our previous experimental studies reported that biochar prepared by pyrolysis at a temperature of 600°C and a residence time of 60 min was more suitable for blast furnace injection [39].

In addition to addressing the economic issue of mass biomass collection and processing, the low fixed carbon, low calorific value, and low energy density of biomass restrict its industrial application. Hydrothermal carbonization (HTC) is a new method of biomass carbonization [40–42]. When compared to conventional pyrolysis technology, HTC offers milder reaction conditions and lower energy consumption [43–44]. HTC technology operates in closed reaction kettles at temperatures ranging from 150 to 400°C for a certain time. During this time, the subcritical water reacts with biomass to form a high carbon content of green products [45]. Approximately 75%–80% of the carbon enters the solid phase products, another 15%–20% dissolves in liquid-phase water, and the remaining 5% is transformed into gases such as CO2 and CH4. Liquid phase products contain more organic components, such as furfural compounds, organic acids, aldehydes, and other components [46], whereas current subcritical water hydrolysis technology is plagued by problems such as the difficult treatment of liquid products and high process costs, which is the bottleneck of large-scale industrial applications. Further research into resource usage and the safe handling of liquid and gas-phase products is required.

Steam explosion is a new technology, which is used in the preparation of hydrogen-rich biochar micropowder. Biomass with a water content of roughly 25% is crushed into 1–2 cm particles and transported by bucket elevator to a high-pressure reactor. At the moment, a bio-manufacturing vehicle system may be created to tackle the collecting issue. As demonstrated in Fig. 3, the H+ and OH− provided by steam will catalyze the transition of the structure and composition of hemicellulose in lignocellulose. During the reaction process, lignin, cellulose, and hemicellulose are self-dismantled, degraded, and converted, and subsequently hydrothermal slurry/semi-coking reaction takes place [47]. Recently, we are experimenting with deoxygenation and carbon enrichment, as well as improving the energy density of biochar. Using biomass as raw material, hydrogen-rich biochar powder has zero carbon emission, high energy density, a calorific value of 21.77–26.38 MJ/kg, the good characteristics of injection, and can substitute coal injection for low fossil fuel ironmaking.

Biomass gasification refers to the process in which biomass polymer is pyrolyzed, oxidized, reduced, and reformed at a certain temperature in the gasifier after simple drying and crushing, and finally, H2 and CO are produced [48]. Higher gas yield and better syngas quality can be obtained by optimizing the gasification agent and parameters. For the biomass gasification, the high efficient and low pollution gasifier is the key. The traditional biomass gasification technologies include fixed bed gasifier, fluidized bed gasifier, airstream bed gasifier, plasma, and other processes based on the different gasifier equipment [49–50]. However, there are several significant issues with traditional gasification equipment and processes: (a) the alkali metal element in some biomass is high, and the alkali metal vapor generated at a high temperature can easily cause equipment corrosion [51]; (b) gasification equipment has high requirements on particle size and moisture content of raw materials, resulting in high pretreatment costs; (c) high tar content in biomass gas leads to low syngas quality and calorific value, as well as low gasification efficiency. Consequently, the key research areas of biomass gasification technology include lowering the tar content of syngas and boosting gasification technology.

The iron and steel industries are in desperate requirement of clean reduced gas to replace coal, coke, natural gas, and other fossil fuels. We combined the demands of the iron and steel industries with the biomass gasification technology and developed two new biomass gasification processes with higher treatment efficiency and more prominent emission reduction effects: the iron bath smelting method [52–53] and the blast furnace method [54]. Iron bath smelting is the process of rapidly pyrolyzing biomass in high-temperature molten iron and slag to produce gas. Fig. 4(a) refers to the technological process of biomass treatment in an iron bath furnace. The biomass particles are immediately thrown into the molten iron bath and break down into hydrocarbons in the molten iron at 1500°C. Hydrogen atoms combine with each other to form hydrogen, and CO is produced when carbon atoms dissolved in the molten iron interact with oxygen atoms dissolved in the molten iron. Harmful components in biomass react with molten iron or slag to generate FeS and CaCl2, which are then dissolved in the slag and discharged. Finally, high-quality bio-syngas is produced with minimal levels of hazardous components and contaminants.

As illustrated in Fig. 4, the blast furnace gas generation technique entails converting small- and medium-sized blast furnaces into biomass gasifiers, as shown in Fig. 4(b). A plasma torch is used as a heat source in the lower part of the furnace to convert electric energy into heat energy. The plasma core reaction zone may reach a high temperature of 3000°C, providing a high-temperature environment for biomass gasification in the lower part of the blast furnace. The organic components of the biomass are oxidized in the high-temperature environment during the descending phase and then transformed into reducing syngas (CO and H2). By installing a row of tuyeres in the upper part of the furnace, adjusting the charging amount and the way of oxygen blown in the upper part, the composition and temperature of syngas can be controlled, which is beneficial to the decomposition of tar in syngas, so as to improve the quality of syngas and reduce energy consumption to the greatest extent. The inorganic components in the biomass are melted at the bottom of the gasifier, and the glass slag is used as roadbed material. This biomass gasifier offers the following benefits over typical biomass gasification equipment: huge processing capacity, large gas production, and compatibility with different types of biomass wastes.

In the practical application of syngas, after injecting hydrogen-rich syngas into the blast furnace, H2 has better penetration because of its lower viscosity and density, and the reduction capacity of H2 is greater than that of CO when the temperature is higher than 810°C, which can improve the indirect reduction and reduce coke consumption. However, in the process of biomass gasification, tar, dust, and other pollutants (ammonia, H2S, and other gas pollutants) would be produced, causing secondary pollution to the environment and limiting the development and use of bio-syngas [55]. The use of water washing and other methods to reduce the content of tar and dust have caused water resource and soil pollution problems. If the cyclone dust collector is installed outside the gasification equipment, dust particles from bio-syngas can be effectively removed; however, the removal of tar and a small number of gas pollutants is a purification problem.

Blast furnace ironmaking is a process with high emissions and high energy consumption. Currently, the injection fuel of the blast furnace is mostly fossils such as bituminous coal and anthracite, posing significant issues for iron and steel firms in the contemporary “dual carbon” background. If a low-carbon emission fuel can be discovered to replace pulverized coal injection (PCI), it will have a better chance in the future if a carbon tax is imposed [56–59].

Much researches have been conducted to investigate the viability of using biomass fuel in blast furnace injection [60–65]. Wang et al. [60] developed a static heat and mass balance model and investigated the replacement rate of charcoal, pyrolysis materials, and wood pellets for blast furnace coal injection and reported that 166.7 kg/t of charcoal could replace 155 kg/t pulverized coal. Pyrolysis material and wood pellets could respectively replace 22.8% and 20% of pulverized coal. By increasing the charcoal injection rate between 200 and 220 kg/t, the net CO2 emissions may be decreased by 40%. Mathieson et al. [64] estimated that using biomass in blast furnace injection would reduce CO2 emissions by 0.4–0.6 t per ton steel.

We discovered that compared with coal, biochar offered higher benefits in injection. As shown in Fig. 5(a)–(b) [35], in comparison to the dense structure of coal, a considerable number of pores were produced on the surface of the palm shell during pyrolysis treatment, which was conducive to the adsorption of gas during combustion and promoted the combustion reaction. In Fig. 5(c) and (d) [35], the results by Raman spectroscopy indicated that the full width at half maxima of G peak (FWHM-G) and ID3+D4/IG (intensity ratio of D3 + D4 peak to G peak) of palm shell char were more than those of pulverized coal, whereas the IG/Iall (intensity ratio of G peak to all peak) of pulverized coal was greater than that of biochar. The order degree of graphitization of pulverized coal was higher than that of palm shell char, thus resulting in palm shell char a higher combustion reactivity. In Fig. 5(e) and (f), in terms of particle size distribution, the distribution of small-size particles in palm shell char was more concentrated, which indicated that the energy consumption of biomass during pulverizing was lower than that of coal [36]. Fig. 5(g) and (h) are the macroscopic morphology of biomass and char. As shown in Fig. 5(i) [35], the palm shell char was smaller than that of pulverized coal, and the microcrystalline layer spacing d002 was as large as that of pulverized coal, indicating that the degree of carbon ordering and graphitization of palm shell char was smaller than that of pulverized coal, resulting in a better combustion reactivity for palm shell char.

We investigated the properties of biochar combustion and its influence on blast furnace operation. As illustrated in Fig. 6(a), the separate combustion of biochar mostly comprises three stages: water extraction (50–128°C), volatilization combustion (219–386°C), and fixed carbon combustion (403–517°C) [66]. The theoretical combustion temperature reaches its maximum and then stays constant when the injection quantity of palm shell char is 15 kg/t, as illustrated in Fig. 6(b). The combustibility of the coal will be substantially increased if the biochar and pulverized coal are mixed. As shown in Fig. 6(c) and (d), the curve shifts to the low-temperature area as the palm shell char ratio increases, indicating an improvement in the mixed combustion performance. Furthermore, if biomass and coal are mixed and injected, there will be a synergistic effect at the tuyere, indicating that injection of biomass helps the combustion of pulverized coal in the tuyere raceway zone. If a large amount of biochar is injected into the tuyere but is not completely burned, the effect of unburned carbon residue on slag viscosity is the same as that for coal. As shown in Fig. 6(e) and (f) [36], slag viscosity increases linearly, so it is necessary to ensure that the biochar is completely consumed in the tuyere raceway [67]. As a result, the impact of biochar on a blast furnace is similar to that of pulverized coal, but it has better combustibility, which has the strong potential to be applied to blast furnace injection.

Biomass gasification is a fairly common type of pretreatment. The collected biomass is put in a biomass gasifier and subjected to high-temperature dry distillation to fracture the macromolecules contained in it, resulting in high value-added bio-syngas of hydrogen with potential for blast furnace applications in the future. The percentage of hydrogen and carbon monoxide in bio-syngas is greater than in natural gas. It can achieve low emissions when used in blast furnace injection, which has broad market prospects.

Some scholars conducted research on the use of syngas for blast furnace injection. Nogami et al. [68] investigated the material and energy balance of the ironmaking system. They revealed that natural gas injection activities minimize CO2 emissions from the ironmaking system while reducing energy input to a minimum. Top gas recycle decrease CO2 emissions because of the scrubbing of CO2 from the recirculated top gas. The simulation research shows that smooth operation of syngas with up to 25 m3 per ton pig iron can be simultaneously achieved by increasing the productivity by 58% and reducing the charged pellet charcoal by 40 kg/t [69].

Because present bio-syngas production cannot fulfill large-scale industrial applications, the mixed injection of syngas and pulverized coal may be used in the future. Fluent software was used to investigate the impact of syngas and pulverized coal on the blast furnace operation. As shown in Fig. 7(a) [70], due to its low temperature, the injected syngas generates a small low-temperature area in the furnace after leaving the injection lance and then interacts with air in tuyere near the wall and burns quickly because of the hot air mixing. The temperature in the center of the pulverized coal flow increases as the temperature increases up to 2583 K, as shown in Fig. 7(b). After that, the temperature in the raceway drops slightly because of both insufficient oxygen and the occurrence of the gasification reaction [71]. Fig. 7(c) and (d) shows the distribution of the gas phase velocity and particle velocity in the model’s middle area. The velocity of the gas is the highest at the outlet of the tuyere’s exit, which is mostly attributed to the reduction of the diameter of the tuyere and the combustion of the gas. After entering the raceway zone, the space suddenly increases, and the velocity of the gas gradually decreases. It can also be seen from the Fig. 7(c) and (d) that the gas velocity at the outlet of the tuyere is the highest, which is caused by the decrease in tuyere diameter and gas combustion. The maximum atmospheric velocity can reach about 273 m/s, and then the space suddenly increases, resulting in the gas velocity gradually decreases after entering the raceway [70]. In Fig. 7(e), it can be observed that when syngas and pulverized coal are burned, the quantity of CO2 and H2O rapidly increases at first and subsequently drops owing to the gasification process, while the mole fraction of CO and H2 keeps increasing. Therefore, it is necessary to study the change rules of these substances under different cases because they are the main reductants in blast furnaces.

The blast furnace process and the sintering process utilize the most energy in the ironmaking process. The energy consumed for sintering accounts for ~9%–12% of the overall energy required to generate hot metal, with solid combustion accounting for ~75%–80%. Using biomass instead of coke powder in the sintering process will help enterprises reduce pollution and carbon.

Some studies on biomass sintering have been conducted by researchers. Because of its high moisture content, low carbon content, and poor calorie value, raw biomass is not suitable for direct use in sintering. According to previous study [72–75], in order to make biochar or charcoal with high fixed carbon and moderate volatility, feedstock biomass must be pyrolyzed. According to Mathieson et al. [76], the use of charcoal in sintering does not result in a reduction in greenhouse gas emissions, but a 5%–15% reduction in net CO2 emissions from steel mills is expected because of biomass carbon neutralization. Gan et al. [77] has reported that the properties of biochar and traditional coke powder are significantly different. Both scanning electron microscopy (SEM) and specific surface analysis (BET) results show that biochar has a large number of micropores and is evenly distributed. The specific surface area for three biochars decreases in the following order: straw char > wood char > fruit pit char [78–79].

The impact of biomass addition on iron ore sintering has been studied [80–81]. The investigation revealed that with the increase in biochar substitution ratio, the combustion front speed increased and the combustible ratio increased, which indicated that the ratio of complete reaction would increase with the biochar addition during the sintering process [82]. Moreover, with the increase in the biochar replacement ratio, the peak concentrations of CO and CO2 generated in the combustion zone increase, so the reduction atmosphere is enhanced, resulting in the inhibition of the formation of calcium ferrite. When biochar replaces coke powder, the temperature of the upper material layer will gradually decrease to a relatively low level, and this change in the upper layer is greater than that in the lower layer [83]. In this situation, the temperature of the layer will decrease to the extent that the mineralization reaction of the sintered material is difficult to occur [84]. Therefore, the addition amount of biochar into sinter raw materials should be carefully studied so as to avoid the bad effect on sinter quality.

The coking process produces a lot of pollutants and consumes a large amount of energy. When biomass is employed, it will decrease pollution emissions, lower the cost of coke production [85]. Coke, as we all know, serves four major purposes in a blast furnace: column skeleton, heat source, reducing agent, and carburization agent. The most crucial function is the skeleton, which is also the reason why coke plays a vital role in blast ironmaking. Therefore, the most important point for biomass-assisted coking is the coke strength after adding biomass. In fact, the addition of biomass will lead to a significant decrease in the strength of coke. According to the research performed by Montiano et al. [86], the addition of sawdust to the mixed coal has a negative influence on the quality of the finished coke product. At lower temperatures, the mass loss of the coal/sawdust mixture is higher than that of pure coal [87–89]. Compared with traditional coke, the strength of coke with 5% and 10% biomass is greatly reduced by 6.2% and 3.3%, respectively. The volatile chemicals emitted from biomass hinder the connection between coal particles during carbonization, which is resulting in a reduction in strength [90]. The pretreated biomass is more suitable for coking, and the coke strength has a close relationship with the pretreatment temperature [91]. When compared to traditional coke, the biomass addition resulted in a considerable increase in the area percentage of particles smaller than 0.5 mm2. There are many single coal particles in the coke after the addition of 5% and 10% biomass. When the addition ratio is 0.2%, the structure of coke is essentially unchanged. When biochar is added to the caking coal, the coal particles are connected. This phenomenon is attributed to the fact that biochar has fewer volatile substances, which will not affect the connectivity between coal particles during the carbonization process.

If iron ore powder can be directly reduced to iron powder, it is bound to be able to use a part of the fine ore or concentrate powder more reasonably and save a lot of energy. Consequently, we conducted extensive research on the direct reduction process of iron ore mixed with biomass. As shown in Fig. 8(a) and (b), with the increase of C/O, the maximum reaction rate increases, the total weight loss increases, and the final reaction fraction increases, but the starting temperature and ending temperature of each stage of the reaction do not significantly change [92]. This shows that a higher carbonization degree does not mean a better reduction effect, and the optimal reduction effect can be achieved when C/O = 1.15. In Fig. 8(c) and (d), the temperature at which biochar begins to rapidly reduce iron ore is 106°C lower than that of pulverized coal and 208°C lower than that of pulverized coke; the maximum reaction rate is 1.57 times that of the reduction of pulverized coal; the final reaction fraction is 17%–20% higher than that of pulverized coal and coke. This suggests that utilizing biochar lowers the reaction temperature of iron ore fines while increasing the reaction rate and ultimate reaction ratio [93]. Moreover, the reducibility of biochar with varied particle sizes to iron ore powder is worth investigating. In Fig. 8(e) and (f) [94], when the particle size of biochar is >0.150 mm, it is necessary to reduce the particle size to promote the reduction of iron ore. However, when the particle size is <0.150 mm, the particle size reduction has no significant impact. Therefore, in powder reduction, the particle size of biochar powder should be controlled below 0.150 mm to achieve a faster reduction.

As shown in Fig. 9(a)–(c) [94], the microscopic morphology of biomass particles is more sharp, while that of iron powder is smoother. In Fig. 9(d)–(j) [94], the reduction rate of composite pellets can be divided into five phases. Magnetite was totally reduced after a 5-min reduction at 850°C. At ~880°C, iron ore started to be converted to metallic Fe and aggregated as iron whiskers. At 900°C, iron whiskers started to expand more. With the increase in temperature, FeO gradually reduced, and the amount of metallic iron gradually grew, causing the iron whiskers to become longer and the bottom diameter to increase [95–99]. At 1050°C, FeO completely disappeared and was completely reduced to metallic iron. The iron whiskers were connected into flakes because of reflow, and a slag phase started to form; at 1200°C, the reduced metal iron aggregated, flowed, and connected into large pieces, and the slag and iron were clearly separated [100–103].

As illustrated in Fig. 10 [94], the self-reduction process of biochar–iron ore composite briquette can be described at the micro and macro levels, respectively. At the microscopic level: (1) in the reaction process of solid carbon-based reducing agent and iron oxides, it is mainly carried out by intermediate gas products CO and CO2; (2) the indirect reduction of iron oxides by CO reduction is the key of the mixture’s self-reduction process; (3) the gasification reaction of solid carbon has a significant impact on the whole reduction process [104–105]. The macroscopic mechanism divides the self-reduction of biomass-containing iron ore into two gas–solid reactions: (1) gasification reaction of flaky biochar particles and (2) indirect reduction reaction of spherical iron oxide particles. The reaction of the gaseous intermediates CO and CO2 results in the reaction of the two solid reactants. In the future, it is necessary to further calculate the kinetics and thermodynamics of the chemical process to identify the limiting factors of these reactions.

Steam explosion, as a biomass pretreatment technology, can be characterized by high efficiency and low energy consumption. It can handle a huge amont of biomass in a short period of time and convert biomass into a particle size appropriate for blast furnace direct injection. This technique matches quite well with today’s “double carbon” background and is also a new technology that large steel firms really require.

The authors preliminarily constructed the process route for hydrogen-rich micropowder production and blast furnace injection based on the properties of hydrogen-rich micropowder, as shown in Fig. 11(a). First, biomass was collected, dried, and ground to the desired particle size before being fed into a transformer flash synthesizer to complete the transformation process from biomass to hydrogen-rich micropowder. There are two methods for transporting hydrogen-rich micropowder to the blast furnace: The first is to carry it in batches and set up an injection tank near the blast furnace. The injection tank space size should be designed according to the actual situation, and then the hydrogen-rich micropowder is injected into the blast furnace. The second is to build a production workshop of biomass hydrogen-rich micropowder inside the ironmaking plant and directly transport the product to the injection tank and then into the blast furnace. The direct injection of hydrogen-rich micropowder will provide significant benefits to the enterprise: for the production enterprise, the existing injection system can be converted to carry out biomass injection with low investment; for new enterprises, it avoids investing a lot of money in pulverizing and conveying equipment. With the efficient utilization of biomass resources, biomass may be utilized for hydrogen-rich micropowder preparation and blast furnace injection with great efficiency [104].

Gases having a high hydrogen concentration, such as coke oven gas and natural gas, are now employed to substitute a portion of pulverized coal for blast furnace injection and participate in the reduction process in the furnace. During hydrogen reduction in the blast furnace, the product of the reduction of iron ore is H2O. With the increase in reducing gas in blast furnaces, the total quantity of CO2 gas generated by blast furnaces decreases, which can effectively boost the iron and steel industries’ energy saving and carbon reduction. However, natural gas and coke oven gas, on the other hand, are still considered fossil fuels, while bio-syngas is a green blast furnace injection fuel with zero carbon emissions and clean environmental protection advantages.

The industrial application route of blast furnace syngas injection is shown in Fig. 11(c). Biomass is treated using hydrogen-rich micropowder technology. Then a high-temperature pressurized airflow bed gasification process is employed to create syngas, and then the temperature in the gasifier is raised to more than 1200°C to produce bio-syngas mainly composed of CO and H2. The high-quality bio-syngas thus obtained can be injected into the blast furnace by two process routes. The first step is to liquefy the syngas and transfer it to the blast furnace tuyere platform through a tanker, and then use a gas heating furnace to heat it to a certain temperature for blast furnace injection. It offers the benefits of low cost and low energy consumption, but it still requires gas heating prior to blast furnace injection. For another better choose, iron and steel companies may construct the gasifier equipment within their plants, and the high-temperature syngas generated by the gasifier can be directly co-produced with the blast furnace. From the point of view of energy utilization, gasifier and metallurgical equipment can co-produce reduction gas for the blast furnace to reduce heat loss and synthetic temperature drop to the greatest extent. From the point of equipment investment, hot gas does not need to be heated, which is an economical and safe way to use it [105].

In China’s iron and steel industry, direct reduction of iron is an important alternative for reducing energy consumption, lowering emissions, and improving steel quality. The significant advantages of the gas-based shaft furnace direct reduction method over other new ironmaking processes are large output per set of equipment, environmental friendliness, low energy consumption, and low pollution emissions. It is an advanced process for the low-carbon, green, and high-quality development of direct reduction ironmaking technology in China. Because China lacks oil and gas resources, the source of reducing gases is critical to the construction of large-scale shaft furnaces. As rich in H2 and CO, bio-syngas has the potential to be used in gas-based direct reduction processes and can be combined with existing direct reduction technologies such as MIDREX, HYL-III, and PERED vertical furnace to form a large-scale combined process for direct reduction iron production [106].

As seen in Fig. 11(d), bio-syngas can be utilized directly in various gas-based direct reduction processes in industrial applications. Shaft furnace gas can also be blended with bio-syngas after the decarbonization process to control the injection temperature so as to achieve the lowest energy consumption and highest energy utilization of shaft furnace. Simultaneously, the iron and steel industries can construct a hydrogen-rich micropowder and gasifier equipment group near the direct reduction furnace to reduce the energy loss and equipment transformation cost of syngas. This design method is the most cost-effective and secure industrial application route. The use of bio-syngas as reductants instead of natural gas and other fossil fuels as reductants in direct reduction ironmaking is of great significance to the promotion of gas-based shaft furnace direct reduction technology in the iron and steel industry in China and the realization of low-carbon and green development of the iron and steel industry.

Typical melting reduction processes such as COREX and HIsmelt still depend on fossil energy sources like coke and pulverized coal, failing to address the issue of fossil energy consumption and carbon emissions at the source. The hydrogen-based melting reduction technique combines hydrogen reduction with the classic melting reduction process, which can realize reducing carbon emission and green development of new frontier technology more effectively. Chinese iron and steel enterprises must not only accelerate research on hydrogen smelting reduction, but also need to build metallurgical equipment and develop hydrogen energy utilization projects in order to open up the hydrogen energy industry chain in the iron and steel industry’s production, storage, and utilization.

Because the structure of hydrogen-rich micropowder is rich in methyl and other light hydrocarbon small molecules as a result of its particular preparation technique, the hydrogen-rich reduction gas dominated by H2 will be generated in the subsequent gasification process. The H2 ratio in bio-syngas can be enhanced, and the path for biomass hydrogen generation can be controlled the preparation conditions and kinds of gasification agents. The purified bio-syngas is used as the hydrogen source in smelting reduction and is injected into the molten iron bath, and then the reducing gas rapidly reduces iron oxide, as illustrated in Fig. 11(e). The bio-syngas can be mixed into the high-temperature reduction gas (CO + H2 > 90%) generated by the shaft furnace to be used as reduction gas. After being heated to 800–850°C and dedusted by the hot cyclone dust collector, the syngas was fed into the gas containment pipe of the upper pre-reduction shaft furnace and then reduced through the descending ore layer from bottom to top. The industrial application design not only addresses the hydrogen source issue of melting reduction but also pushes multi-field and multi-industry “carbon neutralization” across several fields and industries.

Fig. 12(a) [94] shows the changes in carbon balance during biomass-assisted ironmaking. The calculation formula for biomass-assisted ironmaking energy savings and emission reduction was worked out to quantitatively examine the potential of biomass-assisted ironmaking technology to minimize CO2 emissions. According to Fig. 12(b) [94], the blast furnace should use ~500 kg of fuel per ton of iron smelted and emit ~1.49 t of carbon emissions. For every 1 kg of carbon consumption reduction, ~3.67 kg of CO2 can be reduced. According to the calculation results, if the blast furnace operates smoothly and the biomass is completely used in the pre-iron processes such as sintering, pelletizing, coking, and injection, the CO2 emissions of the existing blast furnace ironmaking process can be reduced by >40%.

Furthermore, according to the life cycle evaluation results based on the utilization of biomass into steel mills, the substitution rate of charcoal relative to heavy oil is more than 1.15 times, indicating that the production of 1 t of pig iron requires 90 kg/t of heavy oil, so at least 103.5 kg of charcoal is required [107]. When biomass substitutes for heavy oil, the air consumption will decrease, resulting in a decrease in blast furnace gas. The carbon intake of the blast furnace is lowered by substituting some of the heavy oil and coke. According to Suopajarvi’s findings [107], overall CO2 emissions would be reduced from 4.63 million tons to 3.92 million tons if all-carbon injection were implemented for a steel plant with an annual output of 2.6 million tons of hot-rolled steel. The findings indicate that using biomass into steel production systems can greatly minimize the environmental burden of steel production systems.

Biomass metallurgy will have some economic advantages. The cost of biomass straw for blast furnace injection is listed in this research, using Hebei Province, China as an example. At the moment, in Hebei Province’s “2018 Crop Straw Comprehensive Utilization Project,” it is pointed out that a subsidy of 100 Yuan per ton is available for straw recycling, storage, and transportation, as well as a 50% subsidy for equipment acquisition funds. Based on this, the essential economic characteristics of straw collection and transportation can refer to the application of power plants, and the other detailed costs are shown in Table 1. Among them, the straw carbonization equipment is designed to process 1 ton of straw each time, and the other supporting equipment is primarily drying equipment, water filtration equipment, and carbonization waste collection equipment [108].

| Straw purchase price / (Yuan·t−1) | Straw transportation price / (Yuan·t−1) | Straw carbonization equipment (10 years) / Yuan | Other supporting equipment (10 years) / Yuan | Power consumption/ energy consumption of carbonization process / kWh | Straw purchase and storage subsidies / (Yuan·t−1) | Equipment purchase subsidies / (Yuan·t−1) |

| 140 | 20 | 200000 | 100000 | 100 | 100 | 150000 |

According to Table 1, it can be calculated that the cost of generating 1 ton of straw char using the pyrolysis process in Hebei Province is around 670 Yuan. Other Chinese localities have similarly enacted rules governing the broad use of straw. Due to the “Double Carbon” policy, the market price of anthracite is over 1800 Yuan/t, the price of bituminous coal is about 1200 Yuan/t, and the price of mixed coal is around 1500 Yuan/t for blast furnace injection in the year 2021. At the moment, Europe has begun to levy a carbon tax. With the gradual improvement of the Chinese carbon trading market, steel companies are subject to carbon emission regulations and will choose to acquire carbon emission indicators. Using carbon-neutral biomass as the primary raw material for metallurgy will allow enterprises to break through under the carbon dioxide emission limit.

In comparison to typical fossil fuels (coal, oil, and natural gas), biomass with carbon neutral qualities offers significant benefits as a renewable resource. Based on the authors’ recent research achievements, this study puts forward the concept of biomass metallurgy, introduces some advanced biomass pretreatment methods (steam explosion and gasification), and demonstrates the technical feasibility of biomass applying in the coking, sinter, pellets and blast furnace injection, analyzes the environmental and economic benefits of biomass steelmaking. After appropriate large-scale metallurgical equipment and production processes are mature, biomass may be extensively exploited as a new energy source in steel production in the future.

However, biomass still has several issues that must be addressed: low volume density, high moisture content, high transportation and storage cost and poor grindability. The development of biomass-directed conversion technology and key equipment based on the requirements of thermal and chemical properties of biomass in the metallurgical process is the primary problem to be solved in the large-scale promotion of biomass metallurgy in the future. Moreover, metallurgical process operators must improve the traditional smelting mode, update current metallurgical equipment, and master the operation concept of biomass metallurgy based on the biomass features. Scientific research institutes and the metallurgical industries must work together to address key issues, increase scientific research investment, and constantly deepen the basic theoretical research on biomass metallurgy to truly achieve a green and efficient metallurgy industry.

We declare that we have no financial and personal relationships with other people or organizations that can inapproproately influence our work.

Authors would like to express gratitude to Dr. Zhengwen Hu, Dr. Peng Wang, and Dr. Jing Li for their valuable comments on the manuscript. This work was financially supported by the National Natural Science Foundation of China (No. 51704216), the State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing (Nos. 41620025, 41620026, and 41621009), the Interdisciplinary Research Project for Young Teachers of University of Science and Technology Beijing (Fundamental Research Funds for the Central Universities) (No. FRF-IDRY-20-014).

| [1] |

Z.H. Wang, W.J. Huang, and Z.F. Chen, The peak of CO2 emissions in China: A new approach using survival models, Energy Econ., 81(2019), p. 1099. DOI: 10.1016/j.eneco.2019.05.027

|

| [2] |

A. Kojo Alex, S.J. Wang, H.M. Fang, X.X. Wu, W.S. Chen, and P.L. Che, Review on alternative fuel application in iron ore sintering, Ironmaking Steelmaking, 48(2021), No. 10, p. 1211. DOI: 10.1080/03019233.2021.1950969

|

| [3] |

X. Zhao, X.W Ma, and B.Y Chen, Challenges toward carbon neutrality in China: Strategies and countermeasures, Resour. Conserv. Recycl., 176(2022), art. No. 105959. DOI: 10.1016/j.resconrec.2021.105959

|

| [4] |

Y. Wang, C.H Guo, X.J. Chen, L.Q. Jia, and X.N. Guo, Carbon peak and carbon neutrality in China: Goals, implementation path and prospects, China Geology, 4(2021), No. 4, p. 720.

|

| [5] |

A.P. Slowak and P. Taticchi, Technology, policy and management for carbon reduction: A critical and global review with insights on the role played by the Chinese Academy, J. Cleaner Prod., 103(2015), p. 601. DOI: 10.1016/j.jclepro.2015.01.050

|

| [6] |

S.W. Yu, X. Hu, and L.X. Li, Does the development of renewable energy promote carbon reduction? Evidence from Chinese provinces, J. Environ. Manage., 268(2020), art. No. 110634. DOI: 10.1016/j.jenvman.2020.110634

|

| [7] |

Z.Y. Fan and S.J. Friedmann, Low-carbon production of iron and steel: Technology options, economic assessment, and policy, Joule, 5(2021), No. 4, p. 829. DOI: 10.1016/j.joule.2021.02.018

|

| [8] |

Y.R. Liu and Y.S. Shen, Modelling and optimisation of biomass injection in ironmaking blast furnaces, Prog. Energy Combust. Sci., 87(2021), art. No. 100952. DOI: 10.1016/j.pecs.2021.100952

|

| [9] |

E. Mousa, C. Wang, J. Riesbeck, and M. Larsson, Biomass applications in iron and steel industry: An overview of challenges and opportunities, Renewable Sustainable Energy Rev., 65(2016), p. 1247. DOI: 10.1016/j.rser.2016.07.061

|

| [10] |

M. Abdul Quader, S. Ahmed, S.Z. Dawal, and Y. Nukman, Present needs, recent progress and future trends of energy-efficient ultra-low carbon dioxide (CO2) steelmaking (ULCOS) program, Renewable Sustainable Energy Rev., 55(2016), p. 537. DOI: 10.1016/j.rser.2015.10.101

|

| [11] |

M.A. Quader, S. Ahmed, R.A.R. Ghazilla, S. Ahmed, and M. Dahari, A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing, Renewable Sustainable Energy Rev., 50(2015), p. 594. DOI: 10.1016/j.rser.2015.05.026

|

| [12] |

L.H. Chen, X.B. Li, and W.Y. Wen, The status, predicament and countermeasures of biomass secondary energy production in China, Renewable Sustainable Energy Rev., 16(2012), No. 8, p. 6212. DOI: 10.1016/j.rser.2012.07.006

|

| [13] |

J.U. Nef, An early energy crisis and its consequences, Sci. Am., 237(1977), No. 5, p. 140. DOI: 10.1038/scientificamerican1177-140

|

| [14] |

V. Smil, Energy in world history, Technol. Culture, 36(1994), No. 3, p. 690.

|

| [15] |

H. Suopajärvi, E. Pongrácz, and T. Fabritius, The potential of using biomass-based reducing agents in the blast furnace: A review of thermochemical conversion technologies and assessments related to sustainability, Renewable Sustainable Energy Rev., 25(2013), p. 511. DOI: 10.1016/j.rser.2013.05.005

|

| [16] |

L. Ye, Z.W. Peng, L.C. Wang, A. Anzulevich, I. Bychkov, and D. Kalganov, Use of biochar for sustainable ferrous metallurgy, JOM, 71(2019), No. 11, p. 3931. DOI: 10.1007/s11837-019-03766-4

|

| [17] |

M. Shahabuddin, M.T. Alam, B.B. Krishna, T. Bhaskar, and G. Perkins, A review on the production of renewable aviation fuels from the gasification of biomass and residual wastes, Bioresour. Technol., 312(2020), art. No. 123596. DOI: 10.1016/j.biortech.2020.123596

|

| [18] |

D.P. Ho, H.H. Ngo, and W.S. Guo, A mini review on renewable sources for biofuel, Bioresour. Technol., 169(2014), p. 742. DOI: 10.1016/j.biortech.2014.07.022

|

| [19] |

S.L. Wong, N. Ngadi, T.A.T. Abdullah, and I.M. Inuwa, Current state and future prospects of plastic waste as source of fuel: A review, Renewable Sustainable Energy Rev., 50(2015), p. 1167. DOI: 10.1016/j.rser.2015.04.063

|

| [20] |

P.T. Zhao, Y.F. Shen, S.F. Ge, and K. Yoshikawa, Energy recycling from sewage sludge by producing solid biofuel with hydrothermal carbonization, Energy Convers. Manage., 78(2014), p. 815. DOI: 10.1016/j.enconman.2013.11.026

|

| [21] |

J. Moon, T.Y. Mun, W. Yang, U. Lee, J. Hwang, and E. Jang, Effects of hydrothermal treatment of sewage sludge on pyrolysis and steam gasification, Energy Convers. Manage., 103(2015), p. 401. DOI: 10.1016/j.enconman.2015.06.058

|

| [22] |

J.H. Bao, Z.S. Li, and N.S. Cai, Interaction between iron-based oxygen carrier and four coal ashes during chemical looping combustion, Appl. Energy, 115(2014), p. 549. DOI: 10.1016/j.apenergy.2013.10.051

|

| [23] |

Z. Niu, G.B. Li, D.D. He, X.Z. Fu, W. Sun, and T. Yue, Resource-recycling and energy-saving innovation for iron removal in hydrometallurgy: Crystal transformation of ferric hydroxide precipitates by hydrothermal treatment, J. Hazard. Mater., 416(2021), art. No. 125972. DOI: 10.1016/j.jhazmat.2021.125972

|

| [24] |

V. Dhyani and T. Bhaskar, A comprehensive review on the pyrolysis of lignocellulosic biomass, Renewable Energy, 129(2018), p. 695. DOI: 10.1016/j.renene.2017.04.035

|

| [25] |

B. Xiao, X.F. Sun, and R.C. Sun, Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw, Polym. Degrad. Stab., 74(2001), No. 2, p. 307. DOI: 10.1016/S0141-3910(01)00163-X

|

| [26] |

D. Li, Impact of Torrefaction on Grindability, Hydrophobicity and Fuel Characteristics of Biomass Relevant to Hawaiʻi [Dissertation], University of Hawai'i at Manoa, Manoa, 2015.

|

| [27] |

G.W. Wang, J.L. Zhang, J.Y. Lee, X.M. Mao, L. Ye, and W.R. Xu, Hydrothermal carbonization of maize straw for hydrochar production and its injection for blast furnace, Appl. Energy, 266(2020), art. No. 114818. DOI: 10.1016/j.apenergy.2020.114818

|

| [28] |

Intergovernmental Panel on Climate Change, Anthropogenic and natural radiative forcing, [in] In Climate Change 2013 - The Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, Cambridge University Press, Cambridge, 2013, p. 659.

|

| [29] |

K. Kumar Jha and T.T.M. Kannan, Recycling of plastic waste into fuel by pyrolysis - A review, Mater. Today Proc., 37(2021), p. 3718. DOI: 10.1016/j.matpr.2020.10.181

|

| [30] |

P. Wang, J.L. Zhang, Q.J. Shao, and G.W. Wang, Physicochemical properties evolution of chars from palm kernel shell pyrolysis, J. Therm. Anal. Calorim., 133(2018), No. 3, p. 1271. DOI: 10.1007/s10973-018-7185-z

|

| [31] |

A.R. Mohamed, Z. Hamzah, M.Z.M. Daud, and Z. Zakaria, The effects of holding time and the sweeping nitrogen gas flowrates on the pyrolysis of EFB using a fixed-bed reactor, Procedia Eng., 53(2013), p. 185. DOI: 10.1016/j.proeng.2013.02.024

|

| [32] |

W.J. Liu, W.W. Li, H. Jiang, and H.Q. Yu, Fates of chemical elements in biomass during its pyrolysis, Chem. Rev., 117(2017), No. 9, p. 6367. DOI: 10.1021/acs.chemrev.6b00647

|

| [33] |

W.T. Tsai, M.K. Lee, and Y.M. Chang, Fast pyrolysis of rice husk: Product yields and compositions, Bioresour. Technol., 98(2007), No. 1, p. 22. DOI: 10.1016/j.biortech.2005.12.005

|

| [34] |

X.J. Ning, W. Liang, G.W. Wang, R.S. Xu, P. Wang, and J.L. Zhang, Effect of pyrolysis temperature on blast furnace injection performance of biochar, Fuel, 313(2022), art. No. 122648. DOI: 10.1016/j.fuel.2021.122648

|

| [35] |

P. Wang, G.W. Wang, J.L. Zhang, J.Y. Lee, Y.J. Li, and C. Wang, Co-combustion characteristics and kinetic study of anthracite coal and palm kernel shell char, Appl. Therm. Eng., 143(2018), p. 736. DOI: 10.1016/j.applthermaleng.2018.08.009

|

| [36] |

P. Wang, Basic Research on Application of Biomass Semi-Coke in Blast furnace Injection [Dissertation], University of Science and Technology Beijing, Beijing, 2019.

|

| [37] |

Q.J. Gao, V.L. Budarin, M. Cieplik, M. Gronnow, and S. Jansson, PCDDs, PCDFs and PCNs in products of microwave-assisted pyrolysis of woody biomass – Distribution among solid, liquid and gaseous phases and effects of material composition, Chemosphere, 145(2016), p. 193. DOI: 10.1016/j.chemosphere.2015.11.110

|

| [38] |

G.W. Wang, J.L. Zhang, W.W. Chang, R.P. Li, Y.J. Li, and C. Wang, Structural features and gasification reactivity of biomass chars pyrolyzed in different atmospheres at high temperature, Energy, 147(2018), p. 25. DOI: 10.1016/j.energy.2018.01.025

|

| [39] |

T.S. Farrow, C. Sun, and C.E. Snape, Impact of biomass char on coal char burn-out under air and oxy-fuel conditions, Fuel, 114(2013), p. 128. DOI: 10.1016/j.fuel.2012.07.073

|

| [40] |

D. Basso, F. Patuzzi, D. Castello, M. Baratieri, E.C. Rada, and E. Weiss-Hortala, Agro-industrial waste to solid biofuel through hydrothermal carbonization, Waste Manage., 47(2016), p. 114. DOI: 10.1016/j.wasman.2015.05.013

|

| [41] |

W. Wahyudiono, S. Machmudah, and M. Goto, Utilization of sub and supercritical water reactions in resource recovery of biomass wastes, Eng. J., 17(2013), No. 1, p. 1. DOI: 10.4186/ej.2013.17.1.1

|

| [42] |

M.M. Titirici, A. Thomas, and M. Antonietti, Back in the black: Hydrothermal carbonization of plant material as an efficient chemical process to treat the CO2 problem? New J. Chem., 31(2007), No. 6, p. 787. DOI: 10.1039/b616045j

|

| [43] |

C. He, C.Y. Tang, C.H. Li, J.H. Yuan, K.Q. Tran, and Q.V. Bach, Wet torrefaction of biomass for high quality solid fuel production: A review, Renewable Sustainable Energy Rev., 91(2018), p. 259. DOI: 10.1016/j.rser.2018.03.097

|

| [44] |

N.D. Berge, K.S. Ro, J.D. Mao, J.R.V. Flora, M.A. Chappell, and S. Bae, Hydrothermal carbonization of municipal waste streams, Environ. Sci. Technol., 45(2011), No. 13, p. 5696. DOI: 10.1021/es2004528

|

| [45] |

P. Prawisudha, T. Namioka, and K. Yoshikawa, Coal alternative fuel production from municipal solid wastes employing hydrothermal treatment, Appl. Energy, 90(2012), No. 1, p. 298. DOI: 10.1016/j.apenergy.2011.03.021

|

| [46] |

J. Lu, S.B. Ma, and J.S. Gao, Study on the pressurized hydrolysis dechlorination of PVC, Energy Fuels, 16(2002), No. 5, p. 1251. DOI: 10.1021/ef020048t

|

| [47] |

L.C. Cao, I.K.M. Yu, Y.Y. Liu, X.X. Ruan, D.C.W. Tsang, and A.J. Hunt, Lignin valorization for the production of renewable chemicals: State-of-the-art review and future prospects, Bioresour. Technol., 269(2018), p. 465. DOI: 10.1016/j.biortech.2018.08.065

|

| [48] |

J. Mazumder and H.I. De Lasa, Catalytic steam gasification of biomass surrogates: Thermodynamics and effect of operating conditions, Chem. Eng. J., 293(2016), p. 232. DOI: 10.1016/j.cej.2016.02.034

|

| [49] |

V.S. Sikarwar, M. Zhao, P. Clough, J. Yao, X. Zhong, and M.Z. Memon, An overview of advances in biomass gasification, Energy Environ. Sci., 9(2016), No. 10, p. 2939. DOI: 10.1039/C6EE00935B

|

| [50] |

B. Lemmens, H. Elslander, I. Vanderreydt, K. Peys, L. Diels, and M. Oosterlinck, Assessment of plasma gasification of high caloric waste streams, Waste Manage., 27(2007), No. 11, p. 1562. DOI: 10.1016/j.wasman.2006.07.027

|

| [51] |

X. Han, Y.F. Zhang, D.D. Yao, K.Z. Qian, H.P. Yang, and X.H. Wang, Releasing behavior of alkali and alkaline earth metals during biomass gasification, J. Fuel Chem. Technol., 42(2014), No. 7, p. 792.

|

| [52] |

N. Wang, S. Yu, C.H. Huang, and Z.S. Zou, Simulation of flow and temperature fields in the iron bath vessel, J. Process Eng., 9(2009), Suppl. 1, p. 359.

|

| [53] |

V. Panjkovic, J. Truelove, and O. Ostrovski, Analysis of performance of an iron-bath reactor using computational fluid dynamics, Appl. Math. Modell., 26(2002), No. 2, p. 203. DOI: 10.1016/S0307-904X(01)00056-7

|

| [54] |

V. Wilk and H. Hofbauer, Conversion of fuel nitrogen in a dual fluidized bed steam gasifier, Fuel, 106(2013), p. 793. DOI: 10.1016/j.fuel.2012.12.056

|

| [55] |

J.C. Zhou, S.M. Masutani, D.M. Ishimura, S.Q. Turn, and C.M. Kinoshita, Release of fuel-bound nitrogen during biomass gasification, Ind. Eng. Chem. Res., 39(2000), No. 3, p. 626. DOI: 10.1021/ie980318o

|

| [56] |

R.S. Xu, J.L. Zhang, G.W. Wang, H.B. Zuo, P.C. Zhang, and J.G. Shao, Gasification behaviors and kinetic study on biomass chars in CO2 condition, Chem. Eng. Res. Des., 107(2016), p. 34. DOI: 10.1016/j.cherd.2015.10.014

|

| [57] |

R.S. Xu, W. Wang, and B.W. Dai, Influence of particle size on the combustion behaviors of bamboo char used for blast furnace injection, J. Iron Steel Res., 25(2018), No. 12, p. 1213. DOI: 10.1007/s42243-018-0186-0

|

| [58] |

R.S. Xu, H. Zheng, W. Wang, X. Jiang, Q.G. Liu, and Z.L. Xue, Effect of carbonization temperature on microstructure characters of bamboo char used for blast furnace injection, J. Iron Steel Res., 30(2018), No. 7, p. 515.

|

| [59] |

R.S. Xu, S.L. Deng, W. Wang, J. Schenk, and F.F. Wang, Structural features and combustion behaviour of waste bamboo chopstick chars pyrolysed at different temperatures, Bioenergy Res., 13(2020), No. 2, p. 439. DOI: 10.1007/s12155-020-10095-x

|

| [60] |

C. Wang, M. Larsson, J. Lövgren, L. Nilsson, P. Mellin, and W.H. Yang, Injection of solid biomass products into the blast furnace and its potential effects on an integrated steel plant, Energy Procedia, 61(2014), p. 2184. DOI: 10.1016/j.egypro.2014.12.105

|

| [61] |

H. Suopajärvi, Bioreducer Use in Blast Furnace Ironmaking in Finland: Techno-economic Assessment and CO2 Emission Reduction Potential [Dissertation], University of Oulu, Oulu, 2015.

|

| [62] |

J.A. De Castro, G.D.M. Araújo, I. de Oliveira da Mota, Y. Sasaki, and J.I. Yagi, Analysis of the combined injection of pulverized coal and charcoal into large blast furnaces, J. Mater. Res. Technol., 2(2013), No. 4, p. 308. DOI: 10.1016/j.jmrt.2013.06.003

|

| [63] |

J.G. Mathieson, H. Rogers, M.A. Somerville, and S. Jahanshahi, Reducing net CO2 emissions using charcoal as a blast furnace tuyere injectant, ISIJ Int., 52(2012), No. 8, p. 1489. DOI: 10.2355/isijinternational.52.1489

|

| [64] |

J.G. Mathieson, H. Rogers, and M.A. Somerville, Use of biomass in the iron and steel industry – An Australian perspective, [in] 1st International Conference on Energy Efficiency and CO2 Reduction in the Steel Industry, Dusseldorf, 2011, p. 1.

|

| [65] |

H. Ghanbari, F. Pettersson, and H. Saxén, Sustainable development of primary steelmaking under novel blast furnace operation and injection of different reducing agents, Chem. Eng. Sci., 129(2015), p. 208. DOI: 10.1016/j.ces.2015.01.069

|

| [66] |

J. Li, Preparation and Basic Properties of Biomass Coke for Iron Making [Dissertation], University of Science and Technology Beijing, Beijing, 2012.

|

| [67] |

G. Wang, J. Zhang, J. Shao, Z. Liu, G. Zhang, T. Xu, J. Guo, and H. Wang, Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends, Energy Convers. Manage., 124(2016), pp. 414-426. DOI: 10.1016/j.enconman.2016.07.045

|

| [68] |

H. Nogami, J.I. Yagi, S.Y. Kitamura, and P.R. Austin, Analysis on material and energy balances of ironmaking systems on blast furnace operations with metallic charging, top gas recycling and natural gas injection, ISIJ Int., 46(2006), No. 12, p. 1759. DOI: 10.2355/isijinternational.46.1759

|

| [69] |

H.T. Wang, M.S. Chu, T.L. Guo, W. Zhao, C. Feng, and Z.G. Liu, Mathematical simulation on blast furnace operation of coke oven gas injection in combination with top gas recycling, Steel Res. Int., 87(2016), No. 5, p. 539. DOI: 10.1002/srin.201500372

|

| [70] |

C.L. Zhang, L. Vladislav, R.S. Xu, G. Sergey, K.X. Jiao, and J.L. Zhang, Blast furnace hydrogen-rich metallurgy-research on efficiency injection of natural gas and pulverized coal, Fuel, 311(2022), art. No. 122412. DOI: 10.1016/j.fuel.2021.122412

|

| [71] |

E. Kasai, Y. Hosotani, T. Kawaguchi, K. Nushiro, and T. Aono, Effect of additives on the dioxins emissions in the iron ore sintering process, ISIJ Int., 41(2001), No. 1, p. 93. DOI: 10.2355/isijinternational.41.93

|

| [72] |

T. Kawaguchi and M. Hara, Utilization of biomass for iron ore sintering, ISIJ Int., 53(2013), No. 9, p. 1599. DOI: 10.2355/isijinternational.53.1599

|

| [73] |

E.P.D. Rocha, V.S. Guilherme, J.A. de Castro, Y. Sazaki, and J.I. Yagi, Analysis of synthetic natural gas injection into charcoal blast furnace, J. Mater. Res. Technol., 2(2013), No. 3, p. 255. DOI: 10.1016/j.jmrt.2013.02.015

|

| [74] |

L.M. Lu, Iron Ore: Mineralogy, Processing and Environmental Sustainability, 1st ed., Woodhead Publishing, 2015.

|

| [75] |

L.M. Lu, M. Adam, M. Kilburn, S. Hapugoda, M. Somerville, and S. Jahanshahi, Substitution of charcoal for coke breeze in iron ore sintering, ISIJ Int., 53(2013), No. 9, p. 1607. DOI: 10.2355/isijinternational.53.1607

|

| [76] |

J.G. Mathieson, T. Norgate, S. Jahanshahi, M.A. Somerville, N. Haque, and A. Deev, The potential for charcoal to reduce net greenhouse gas emissions from the Australian steel industry, [in] Proceeding of 6th International Congress on the Science and Technology of Ironmaking (ICSTI), Rio deJaneiro, Brazil, 2012.

|

| [77] |

M. Gan, X. Fan, Z. Ji, X. Chen, T. Jiang, and Z. Yu, Effect of distribution of biomass fuel in granules on iron ore sintering and NOx emission, Ironmaking Steelmaking, 41(2014), No. 6, p. 430. DOI: 10.1179/1743281213Y.0000000138

|

| [78] |

X.H. Fan, Z.Y. Ji, and M. Gan, Application of biomass fuel to iron ore sintering, J. Cent. South Univ., 44(2013), No. 5, p. 1747.

|

| [79] |

M. Gan, X.H. Fan, X.L. Chen, Z.Y. Ji, W. Lv, and Y. Wang, Reduction of pollutant emission in iron ore sintering process by applying biomass fuels, ISIJ Int., 52(2012), No. 9, p. 1574. DOI: 10.2355/isijinternational.52.1574

|

| [80] |

X.H. Fan, M. Gan, T. Jiang, X.L. Chen, and L.S. Yuan, Decreasing bentonite dosage during iron ore pelletising, Ironmaking Steelmaking, 38(2011), No. 8, p. 597. DOI: 10.1179/1743281211Y.0000000029

|

| [81] |

M. Gan, X.H. Fan, Z.H. Zhang, X.J. Zhou, Y.Q. Wang, and H.J. Yu, Fundamental research on applying organic binder SHN to oxidized pellets, J. Iron Steel Res. Int., 16(2009), p. 327.

|

| [82] |

M. Gan, Z.Y. Ji, X.H. Fan, W. Lv, R.Y. Zheng, and X.L. Chen, Preparing high-strength titanium pellets for ironmaking as furnace protector: Optimum route for ilmenite oxidation and consolidation, Powder Technol., 333(2018), p. 385. DOI: 10.1016/j.powtec.2018.04.042

|

| [83] |

Y.Q. Zhao, T.C. Sun, H.Y. Zhao, C. Chen, and X.P. Wang, Effect of reductant type on the embedding direct reduction of beach titanomagnetite concentrate, Int. J. Miner. Metall. Mater., 26(2019), No. 2, p. 152. DOI: 10.1007/s12613-019-1719-7

|

| [84] |

X.H. Fan, M. Gan, T. Jiang, L.S. Yuan, and X.L. Chen, Influence of flux additives on iron ore oxidized pellets, J. Cent. South Univ. Technol., 17(2010), No. 4, p. 732. DOI: 10.1007/s11771-010-0548-7

|

| [85] |

J. Zhao, H.B. Zuo, J.S. Wang, and Q.G. Xue, The mechanism and products for co-thermal extraction of biomass and low-rank coal with NMP, Int. J. Miner. Metall. Mater., 26(2019), No. 12, p. 1512. DOI: 10.1007/s12613-019-1872-z

|

| [86] |

M.G. Montiano, E. Díaz-Faes, C. Barriocanal, and R. Alvarez, Influence of biomass on metallurgical coke quality, Fuel, 116(2014), p. 175. DOI: 10.1016/j.fuel.2013.07.070

|

| [87] |

M.W. Seo, H.M. Jeong, W.J. Lee, S.J. Yoon, H.W. Ra, and Y.K. Kim, Carbonization characteristics of biomass/coking coal blends for the application of bio-coke, Chem. Eng. J., 394(2020), art. No. 124943. DOI: 10.1016/j.cej.2020.124943

|

| [88] |

M.A. Diez, R. Alvarez, and M. Fernández, Biomass derived products as modifiers of the rheological properties of coking coals, Fuel, 96(2012), p. 306. DOI: 10.1016/j.fuel.2011.12.065

|

| [89] |

T. Matsumura, M. Ichida, T. Nagasaka, and K. Kato, Carbonization behaviour of woody biomass and resulting metallurgical coke properties, ISIJ Int., 48(2008), No. 5, p. 572. DOI: 10.2355/isijinternational.48.572

|

| [90] |

Z.W. Hu, J.L. Zhang, H.B. Zuo, M. Tian, Z.J. Liu, and T.J. Yang, Substitution of biomass for coal and coke in ironmaking process, Adv. Mater. Res., 236-238(2011), p. 77. DOI: 10.4028/www.scientific.net/AMR.236-238.77

|

| [91] |

H. Wang, Experimental Study on Coking of Biomass Blended Coal [Dissertation], Wuhan University of Science and Technology, Wuhan, 2015.

|

| [92] |

H.B. Zuo, Z.W. Hu, J.L. Zhang, J. Li, and Z.J. Liu, Direct reduction of iron ore by biomass char, Int. J. Miner. Metall. Mater., 20(2013), No. 6, p. 514. DOI: 10.1007/s12613-013-0759-7

|

| [93] |

J.L. Zhang, J. Guo, G.W. Wang, T. Xu, Y.F. Chai, and C.L. Zheng, Kinetics of petroleum coke/biomass blends during co-gasification, Int. J. Miner. Metall. Mater., 23(2016), No. 9, p. 1001. DOI: 10.1007/s12613-016-1317-x

|

| [94] |

Z.W. Hu, Basic Research on CO2 Emission Reduction of Iron Smelting Assisted by Biomass Energy [Dissertation], University of Science and Technology Beijing, Beijing, 2013.

|

| [95] |

D.B. Guo, M. Hu, C.X. Pu, B. Xiao, Z.Q. Hu, and S.M. Liu, Kinetics and mechanisms of direct reduction of iron ore-biomass composite pellets with hydrogen gas, Int. J. Hydrogen Energy, 40(2015), No. 14, p. 4733. DOI: 10.1016/j.ijhydene.2015.02.065

|

| [96] |

D.B. Guo, L.D. Zhu, S. Guo, B.H. Cui, S.P. Luo, and M. Laghari, Direct reduction of oxidized iron ore pellets using biomass syngas as the reducer, Fuel Process. Technol., 148(2016), p. 276. DOI: 10.1016/j.fuproc.2016.03.009

|

| [97] |

D.B. Guo, Y.B. Li, B.H. Cui, Z.H. Chen, S.P. Luo, and B. Xiao, Direct reduction of iron ore/biomass composite pellets using simulated biomass-derived syngas: Experimental analysis and kinetic modelling, Chem. Eng. J., 327(2017), p. 822. DOI: 10.1016/j.cej.2017.06.118

|

| [98] |

M. Zandi, M. Martinez-Pacheco, and T.A.T. Fray, Biomass for iron ore sintering, Miner. Eng., 23(2010), No. 14, p. 1139. DOI: 10.1016/j.mineng.2010.07.010

|

| [99] |

P. Yuan, B.X. Shen, D.P. Duan, G. Adwek, X. Mei, and F.J. Lu, Study on the formation of direct reduced iron by using biomass as reductants of carbon containing pellets in RHF process, Energy, 141(2017), p. 472. DOI: 10.1016/j.energy.2017.09.058

|

| [100] |

Q. Hu, D.D. Yao, Y.P. Xie, Y.J. Zhu, H.P. Yang, and Y.Q. Chen, Study on intrinsic reaction behavior and kinetics during reduction of iron ore pellets by utilization of biochar, Energy Convers. Manage., 158(2018), p. 1. DOI: 10.1016/j.enconman.2017.12.037

|

| [101] |

H.B. Zuo, W.W. Geng, J.L. Zhang, and G.W. Wang, Comparison of kinetic models for isothermal CO2 gasification of coal char-biomass char blended char, Int. J. Miner. Metall. Mater., 22(2015), No. 4, p. 363. DOI: 10.1007/s12613-015-1081-3

|

| [102] |

D. Cholico-González, N.O. Lara, M.A.S. Miranda, R.M. Estrella, R.E. García, and C.A.L. Patiño, Efficient metallization of magnetite concentrate by reduction with agave bagasse as a source of reducing agents, Int. J. Miner. Metall. Mater., 28(2021), No. 4, p. 603. DOI: 10.1007/s12613-020-2079-z

|

| [103] |

Y. Ueki, Y. Nunome, R. Yoshiie, I. Naruse, Y. Nishibata, and S. Aizawa, Effect of woody biomass addition on coke properties, ISIJ Int., 54(2014), No. 11, p. 2454. DOI: 10.2355/isijinternational.54.2454

|

| [104] |

H. Konishi, K. Ichikawa, and T. Usui, Effect of residual volatile matter on reduction of iron oxide in semi-charcoal composite pellets, ISIJ Int., 50(2010), No. 3, p. 386. DOI: 10.2355/isijinternational.50.386

|

| [105] |

Z.W. Hu, J.L. Zhang, H.B. Zuo, Z.J. Liu, and T.J. Yang, Applications and prospects of bio-energy in ironmaking process, [in] 2010 the Second China Energy Scientist Forum, Xuzhou, 2010, p. 708.

|

| [106] |

Y. Dong, X.X. Qiao, G.H. Liu, J.N. Jia, Z.R. Geng, and S.L. Zhao, Research situation of reduction gas used in gas-based direct reduction iron technology, Energy Energy Conserv., 2016, No. 3, p. 2.

|

| [107] |

H. Suopajärvi and T. Fabritius, Effects of biomass use in integrated steel plant - gate-to-gate life cycle inventory method, ISIJ Int., 52(2012), No. 5, p. 779. DOI: 10.2355/isijinternational.52.779

|

| [108] |

W. Xiong, G.Q. Wang, and S.X. Zhou, Comparison of energy consumption and environmental impact of replacement of coal with straw injection into blast furnace, Environ. Sci. Technol., 36(2013), No. 4, p. 137.

|

| [1] | Ya-yun Wang, Hui-fen Yang, Bo Jiang, Rong-long Song, Wei-hao Zhang. Comprehensive recovery of lead, zinc, and iron from hazardous jarosite residues using direct reduction followed by magnetic separation [J]. International Journal of Minerals, Metallurgy and Materials, 2018, 25(2): 123-130. DOI: 10.1007/s12613-018-1555-1 |

| [2] | Rui-min Jiao, Peng Xing, Cheng-yan Wang, Bao-zhong Ma, Yong-Qiang Chen. Recovery of iron from copper tailings via low-temperature direct reduction and magnetic separation:process optimization and mineralogical study [J]. International Journal of Minerals, Metallurgy and Materials, 2017, 24(9): 974-982. DOI: 10.1007/s12613-017-1485-3 |

| [3] | Yi-min Zhang, Ling-yun Yi, Li-na Wang, De-sheng Chen, Wei-jing Wang, Ya-hui Liu, Hong-xin Zhao, Tao Qi. A novel process for the recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite:sodium modification-direct reduction coupled process [J]. International Journal of Minerals, Metallurgy and Materials, 2017, 24(5): 504-511. DOI: 10.1007/s12613-017-1431-4 |

| [4] | Zhi-guo Liu, Ti-chang Sun, Xiao-ping Wang, En-xia Gao. Generation process of FeS and its inhibition mechanism on iron mineral reduction in selective direct reduction of laterite nickel ore [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(9): 901-906. DOI: 10.1007/s12613-015-1148-1 |

| [5] | Zhuo-fei Cai, Zhi-mei Zhang, Zhan-cheng Guo, Hui-qing Tang. Direct electrochemical reduction of solid vanadium oxide to metal vanadium at low temperature in molten CaCl2-NaCl [J]. International Journal of Minerals, Metallurgy and Materials, 2012, 19(6): 499-505. DOI: 10.1007/s12613-012-0586-2 |

| [6] | G. A. Habeeb, H. B. Mahmud, N. B. A. A. Hamid. Assessment of deterioration in RHA-concrete due to magnesium sulphate attack [J]. International Journal of Minerals, Metallurgy and Materials, 2010, 17(6): 691-696. DOI: 10.1007/s12613-010-0375-8 |

| [7] | Lijin Shen, Xuguang Wang. Thermal stability assessment of anti-explosive ammonium nitrate [J]. International Journal of Minerals, Metallurgy and Materials, 2005, 12(1): 12-15. |

| [8] | Aixue Sha, Lüren Dong, Shangyi Li. Thermodynamic Assessment of Reactions between Yttrium and Tramp Elements in Petroleum Pipe Steel [J]. International Journal of Minerals, Metallurgy and Materials, 1998, 5(4): 219-222. |

| [9] | Xianran Xing, Thiyu Qiao, Herbert IPser. Re-assessment and Optimization of the Ga-M (M = In, Sb,Pb) Systems with Chemsage [J]. International Journal of Minerals, Metallurgy and Materials, 1998, 5(4): 212-218. |